In the global agricultural supply chain, the journey of produce from farm to table is fraught with challenges. Among the most delicate of these commodities is the onion, a staple in cuisines worldwide yet notoriously prone to spoilage. For growers, distributors, and retailers, the critical question arises: what is the most effective way to preserve onion quality and extend shelf life? The answer often lies not just in temperature control, but in the primary packaging itself. This brings us to a pivotal inquiry: Are specialized onion mesh bags truly essential for storage? The evidence, grounded in post-harvest science and practical logistics, points overwhelmingly to yes.

Understanding the Physiology of Onion Storage

To appreciate the value of proper packaging, one must first understand the onion's behavior after harvest. Onions are living organs that continue to respire, taking in oxygen and releasing carbon dioxide, heat, and moisture. This process does not stop after they are pulled from the ground. Trapped heat and moisture are the primary enemies of stored onions, creating an ideal environment for microbial growth, mold formation, and premature sprouting. Furthermore, physical bruising and pressure damage during stacking and transport can render entire batches unsellable. Therefore, the ideal packaging must master a delicate balance: providing structural support without sacrificing breathability.

The Scientific Design of Onion Mesh Bags

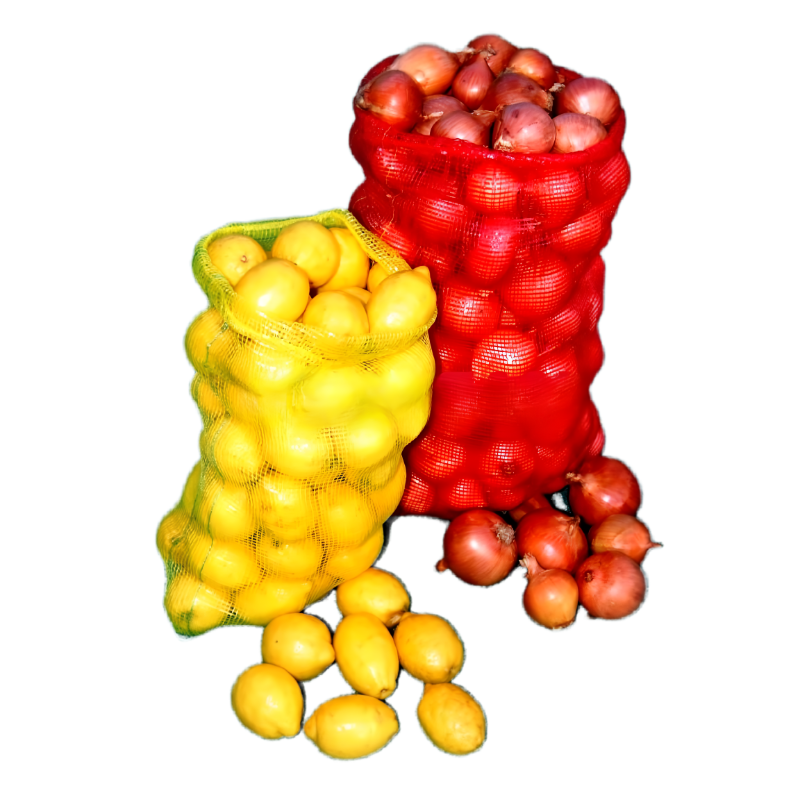

This is where the specialized design of onion mesh bags proves its indispensability. Unlike solid woven bags or sealed plastic packaging, these bags are engineered with a precise open-weave structure, typically as Leno or Raschel mesh bags. This design is not arbitrary; it is a direct response to the onion's storage requirements.

1.Superior Ventilation and Breathability: The paramount advantage of onion mesh bags is their unparalleled airflow. The mesh structure facilitates 360-degree ventilation, allowing the constant dissipation of respiratory heat and water vapor. This dramatically reduces the risk of condensation and rot, effectively putting the onions in a state of "suspended animation" that prolongs freshness and firmness for extended periods. For long-haul shipping or bulk storage, this breathability is not a luxury—it is a necessity for maintaining product integrity.

2.Remarkable Strength and Damage Prevention: Constructed from high-grade, UV-stabilized Polypropylene (PP), these bags offer a surprising strength-to-weight ratio. They are designed to resist tearing and puncturing under the weight of heavy stacking, safeguarding the onions inside from impact and crushing. The flexible nature of the mesh also allows for slight movement, which can help absorb shocks during transit better than rigid containers.

3.Enhanced Visibility and Quality Assurance: The open mesh provides immediate visual access to the contents. Retailers and end-consumers can quickly assess the quality, size, and condition of the onions without needing to open the bag. This transparency builds trust and reduces the likelihood of returns. Additionally, the bag surface serves as a perfect platform for high-visibility branding, allowing producers to print logos and product information, thereby turning a utilitarian item into a powerful marketing tool.

4.Alignment with Modern Sustainability Goals: In today's eco-conscious market, the environmental profile of packaging is a significant factor. Many modern onion mesh bags are available in recyclable or biodegradable formulations. This allows businesses to meet consumer demand for sustainable practices and reduce their environmental footprint, adding a valuable green credential to their operations.

A Comparative Analysis: Why Alternatives Fall Short

Let's briefly examine why other common packaging options are less suitable for onions:

1.Solid Woven PP Bags: While strong and cost-effective, their limited breathability often leads to moisture entrapment and localized spoilage, making them a risky choice for long-term onion storage.

2.Paper Sacks: Highly susceptible to moisture, paper sacks lose their structural integrity in humid conditions, leading to collapses and increased handling damage.

3.Closed Plastic Crates/Bins: Without dedicated and often costly ventilation systems, these containers can become "sweat boxes," accelerating decay rather than preventing it.

The onion mesh bag stands out by successfully integrating breathability, strength, and cost-efficiency into a single, optimized solution.

Selecting the Right Onion Mesh Bag for Your Needs

Not all mesh bags are created equal. To ensure optimal performance, consider these specifications:

Mesh Density: The hole size must be appropriate for the onion variety to prevent protrusion or snagging while ensuring maximum airflow.

Load Capacity: Ensure the bag's tensile strength is rated for your intended fill weight (e.g., 10kg, 25kg) and the pressures of palletization.

Material Quality: Partner with a manufacturer who uses food-safe, virgin materials to guarantee hygiene and performance consistency.

Customization: A reliable supplier will offer options for various colors, sizes, and high-quality printing to support your brand identity.

Conclusion: An Indispensable Tool for the Modern Supply Chain

In conclusion, the question of whether onion mesh bags are essential for storage can be answered with a resounding affirmative. They are far more than just a container; they are a technologically simple yet profoundly effective climate management system. By directly addressing the core physiological challenges of onion storage—respiration and physical damage—these bags play a direct role in reducing waste, preserving quality, and protecting profitability.

For any stakeholder in the agricultural value chain, investing in high-performance onion mesh bags is a strategic decision. It is an investment that pays dividends by ensuring that a high-quality product arrives in the market, ready to meet the discerning standards of retailers and consumers alike.